In the world of CNC machining, precision and efficiency are paramount. To achieve the highest level of accuracy, modern CNC machine shops are turning to advanced technologies such as touch probes. A touch probe is a versatile tool used in CNC milling applications to enhance the precision and efficiency of the machining process. By providing automated measurements and feedback, touch probes play a vital role in optimizing productivity, improving quality, and reducing costs. In this article, we will delve into the intricacies of touch probes, their usage in CNC milling, and the myriad benefits they bring to the manufacturing industry.

What is a Touch Probe in CNC Machining?

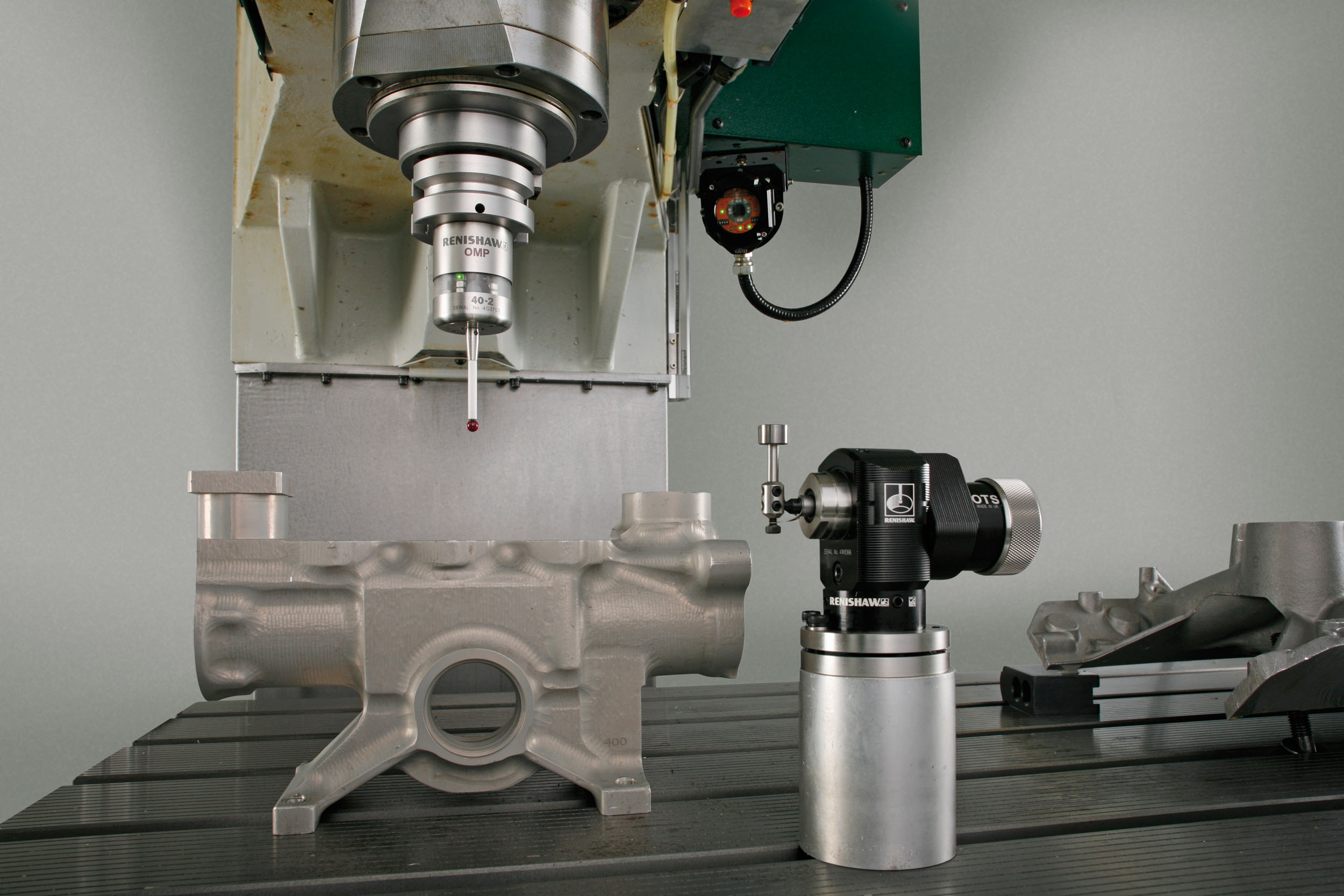

A touch probe is an electronic device mounted on a CNC machine that uses sensors to precisely measure the position and dimensions of the workpiece. It is commonly used for part inspection, tool setting, workpiece alignment, and adaptive machining. Touch probes are available in various designs, including mechanical and optical variants, each tailored to specific applications.

How is a Touch Probe Used in CNC Machine Shops?

During CNC milling operations, a touch probe performs several critical functions that enhance accuracy and efficiency:

- Workpiece Alignment: Touch probes enable the precise alignment of the workpiece by measuring reference points or features. This ensures that the workpiece is positioned correctly, minimizing errors in subsequent machining operations.

- Tool Setting: Touch probes accurately measure the length, diameter, and position of cutting tools. This information is used to set tool offsets, ensuring optimal tool performance and reducing the risk of tool breakage or damage to the workpiece.

- Part Inspection: Touch probes enable in-process inspection by measuring critical dimensions, checking for part features, and verifying tolerances. This real-time feedback allows for immediate adjustments, ensuring the part meets the required specifications.

- Adaptive Machining: Touch probes facilitate adaptive machining techniques by measuring the actual dimensions of machined features. This information can be used to adjust tool paths, compensate for tool wear, and correct for any variations in the workpiece, leading to improved accuracy and reduced scrap rates.

Benefits of Using a Touch Probe in CNC Machine Shops:

- Enhanced Precision: Touch probes provide highly accurate measurements, surpassing human capabilities. By automating measurement tasks, touch probes eliminate human error and variability, resulting in consistently precise machining operations. This heightened precision translates into higher-quality finished products.

- Improved Efficiency: The automation provided by touch probes significantly reduces manual intervention and saves valuable machining time. By automating processes such as workpiece alignment and tool setting, touch probes streamline the setup process, increasing overall machine utilization and reducing production cycle times.

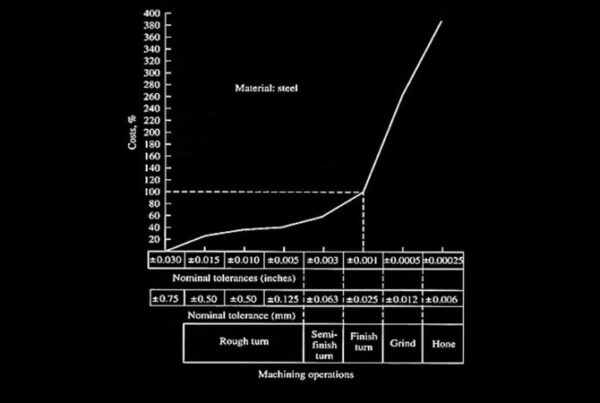

- Cost Reduction: Touch probes contribute to cost savings in multiple ways. Firstly, by minimizing errors and scrap rates, they reduce material waste and associated costs. Secondly, touch probes enable lights-out machining, allowing for unattended operation during non-working hours, maximizing machine utilization and throughput. This extended production time reduces labor costs and increases productivity.

- Risk Mitigation: Touch probes enhance operator safety by minimizing the need for manual intervention near rotating cutting tools. With the touch probe taking measurements and verifying part alignment, operators can work at a safer distance, reducing the risk of accidents and injuries.

- Process Optimization: Touch probes provide real-time feedback on part dimensions and tool wear, enabling immediate adjustments to optimize the machining process. By adapting tool paths, feed rates, and other parameters, touch probes ensure that each machining operation is optimized for maximum efficiency and quality.

- Advanced Inspection Capabilities: Touch probes equipped with sophisticated measurement software can perform complex inspections, including geometric dimensioning and tolerancing (GD&T) measurements. This capability allows for comprehensive verification of part features, ensuring compliance with design specifications and industry standards.

Touch Probes are Necessary for CNC Machine Shop Excellence

In the CNC machine shop environment, where precision and efficiency are critical, touch probes have emerged as invaluable tools. Their ability to automate measurements, enhance precision, and optimize machining processes brings numerous benefits to manufacturers. From improving quality through increased accuracy to reducing costs through automation, touch probes play a crucial role in driving productivity and competitiveness. As CNC machining continues to advance, touch probes will undoubtedly remain indispensable tools for achieving the highest levels of precision and efficiency in the manufacturing industry.