Creating a high-quality design while keeping cost and ease of production in mind can be challenging. Let’s look at three essential areas in designing for manufacturability (DFM) and provide several tips to help you get started.

What is “Design for Manufacturability?”

Design for manufacturability, or DFM, is the process of designing a part or assembly with its manufacturing process in mind. The goal is to create a design that meets function and quality requirements, which can be produced in the easiest and cheapest way possible.

Who Should Be Involved in DFM?

When designing a part for manufacturability, all stakeholders should be involved, including design and manufacturing engineers, quality (inspection), purchasing (material procurement), marketing, and vendors supplying materials and components. Involving all stakeholders early in the process helps identify and resolve potential issues during the design phase, saving time and money.

Effective communication among all parties is crucial. Everyone must understand the engineering drawings to avoid overlooking design problems.

Factors Influencing Manufacturability and Cost

There are several factors to consider when creating a new design. The involvement of stakeholders can highlight potential issues early, resulting in significant cost savings. This is particularly important considering the “Rule of 10,” which states that the cost of making a change increases tenfold at each subsequent phase of product development.

For example, making a change during the testing phase costs ten times more than in the design phase, and making a change during production costs 100 times more than during design. This underscores the importance of a knowledgeable design team.

Key Considerations in Design for Manufacturability

1. Design Component Parts for Ease of Fabrication

When designing a part for easy manufacturing, consider the following:

- Use Off-the-Shelf Parts: If an existing part can fulfill the function, use it instead of designing a new one to reduce costs.

- Use Common Parts: If off-the-shelf parts aren’t suitable, use parts already in use in other assemblies to reduce inventory.

- Material Considerations: Select common materials that are easier to procure and compatible with your existing manufacturing equipment.

- Concurrently Design the Part and Its Tooling: Understand the manufacturing process and equipment capabilities to design the required tooling alongside the part.

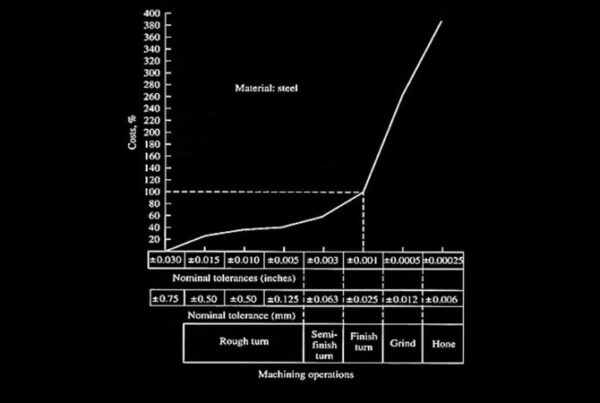

- Optimal Part Tolerances: Determine tolerances based on part function. Tight tolerances increase production costs and reject rates.

2. Design for Ease of Assembly

Consider how the part will be assembled into the final product to simplify the assembly process:

- Optimal Tolerances: Use Geometric Dimensioning and Tolerancing (GD&T) to ensure proper part fit within the assembly, focusing on functional requirements.

- Simplify Part Differences: Make differences between similar parts obvious through markings or colors to prevent assembly errors.

- Design for Symmetry: Design parts symmetrically to eliminate orientation issues during assembly.

- Reduce Total Number of Parts: Fewer parts in the assembly reduce assembly time and potential errors.

- Use Subassemblies: Simplify top-level designs by using subassemblies, allowing updates without affecting the entire assembly.

- Easy and Quick Fastening Methods: Implement fastening methods that simplify and speed up the assembly process.

3. Design for Inspection

Designing for inspection ensures the part meets quality standards efficiently:

- Clearly Indicate Functional Requirements: Use GD&T to show functional importance and inspection setup on drawings, ensuring proper measurement.

- Indicate Inspection Setup: Include datums on drawings to specify how parts should be measured, ensuring repeatable measurements.

- Design for Functional Gauges: Create designs that allow for quick and easy inspection using functional gauges by designing for Maximum Material Condition (MMC). Calculate the worst-case condition (Virtual Condition) to create effective functional gauges.

Summary

Designing for manufacturability involves considering ease of fabrication, assembly, and inspection. Involving all stakeholders and ensuring effective communication can significantly reduce costs and production issues. By focusing on these key areas, you can create a quality product that is cost-effective and easier to produce and inspect.