In the fast-evolving landscape of manufacturing, the integration of advanced technologies including robotics and AI is poised to redefine how industries operate. The aerospace and defense sectors, known for their high precision and stringent standards, are at the forefront of adopting these cutting-edge technologies. As we look toward the future, the convergence of robotics, computer vision, and artificial intelligence (AI) promises to usher in a new era of manufacturing—one that is more efficient, intelligent, and collaborative.

In this article, we will explore three pivotal areas: the impact of computer vision on robotics, the transformative role of AI, and the implications of natural language communication with robots.

1. The Power of Computer Vision in Robotics

Computer vision is revolutionizing the capabilities of robots by enabling them to perceive and interpret their surroundings with unprecedented accuracy. In manufacturing, this means robots can perform complex tasks with a level of precision and adaptability that was previously unattainable. Vision gives robots the closed-loop feedback that is missing with most robotic applications today.

Enhanced Accuracy and Quality Control

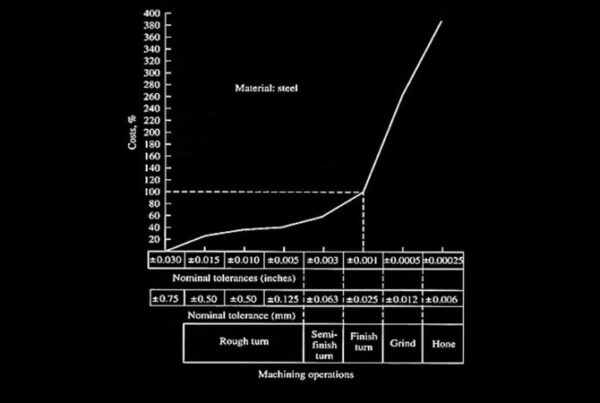

With computer vision, robots can identify defects, measure dimensions, and ensure quality with exceptional precision. In the aerospace and defense industries, where even minor imperfections can have significant consequences, this technology is invaluable. For instance, robots equipped with high-resolution cameras and advanced image processing algorithms can inspect aircraft components, detecting microscopic cracks or irregularities that human eyes might miss. This not only improves product quality but also potentially reduces cost structure.

Adaptive Manufacturing Processes

Computer vision allows robots to adapt to changes in the manufacturing environment in real time. They can recognize different parts, understand their orientations, and adjust their actions accordingly. This capability is crucial in industries where customization and small-batch production are becoming more common. For example, in the assembly of specialized aerospace components, robots can seamlessly switch between different tasks and configurations, reducing downtime and increasing productivity.

Collaborative Robotics

Robots with computer vision can work alongside human operators in a collaborative manner. They can interpret gestures, follow visual cues, and even predict human actions. This interaction enhances the synergy between humans and robots, allowing for more efficient and flexible manufacturing processes. In a defense manufacturing setting, this could mean robots assisting technicians in assembling intricate devices, handing over tools, or even learning from human experts through visual observation.

2. The Transformative Role of AI in Robotics

Artificial intelligence is the brain that will eventually power modern robotics, enabling machines to learn, reason, and make decisions. The integration of AI with robotics will transform manufacturing in several profound ways.

Autonomous Decision-Making

AI algorithms enable robots to analyze vast amounts of data, recognize patterns, and make decisions autonomously. In manufacturing, this means robots can optimize production processes, predict maintenance needs, and adjust operations to minimize downtime. For example, AI-powered robots in an aerospace manufacturing plant can monitor their own performance, anticipate when parts will wear out, and schedule maintenance without human intervention. Eventually, these autonomous agents will also be empowered to optimize production schedules.

Bespoke Manufacturing

AI enables robots to handle the complexities of bespoke manufacturing. By analyzing customer data and preferences, AI can guide robots to produce customized products on demand. In the aerospace industry, this could translate to the production of bespoke components tailored to specific aircraft models or customer requirements. The ability to offer personalized manufacturing at scale opens up new business opportunities and enhances customer satisfaction.

Continuous Learning and Improvement

One of the most significant advantages of AI is its ability to learn and improve over time. Machine learning algorithms allow robots to refine their actions based on feedback and new data. This continuous learning loop ensures that manufacturing processes are always optimized. In defense manufacturing, where precision and consistency are paramount, AI-driven robots can continually enhance their performance, ensuring that every component meets the highest standards.

3. The Impact of Natural Language Communication

The ability to communicate with robots using natural language is a game-changer for manufacturing. When robots understand and respond to human speech, the interaction between humans and machines becomes more intuitive and efficient.

Streamlined Operations

Natural language communication simplifies the way operators interact with robots. Instead of programming esoteric, complex instructions, operators can give verbal commands, making the process more accessible and reducing the need for specialized training. In an aerospace manufacturing facility, a technician could instruct a robot to adjust its position, change tools, or start a new task using simple spoken commands. This ease of communication accelerates operations and reduces the likelihood of errors.

Enhanced Collaboration

When robots can understand and respond to human speech, collaboration becomes more fluid. Workers can ask robots for assistance, clarify instructions, and receive immediate feedback. This real-time interaction fosters a collaborative environment where humans and robots work together seamlessly. In defense manufacturing, where teamwork is critical, this capability enhances productivity and ensures that complex projects are completed efficiently.

Human-Robot Relationship

The ability to speak to robots as if they were human transforms the nature of the human-robot relationship. It humanizes robots, making them more approachable and easier to integrate into the workforce. This shift is particularly important in industries like aerospace and defense, where the complexity of tasks and the need for precision can make the adoption of new technologies challenging. By making robots more user-friendly, natural language communication accelerates their adoption and integration into manufacturing processes.

The Future of Robotics in Manufacturing

The future of robotics in manufacturing is bright, driven by advancements in computer vision, artificial intelligence, and natural language processing. As robots become more capable of seeing, understanding, and interacting with the world around them, they will play an increasingly central role in manufacturing processes. For the aerospace and defense industries, these advancements promise to enhance precision, efficiency, and collaboration, driving innovation and growth.

By embracing these technologies, manufacturers can not only improve their operations but also pave the way for a new era of intelligent, responsive, and adaptable manufacturing. The journey towards this future is already underway, and the possibilities are limitless.